CATALOG

Quality control at all stages of production, from the supply of materials to the shipment of equipment to the client!

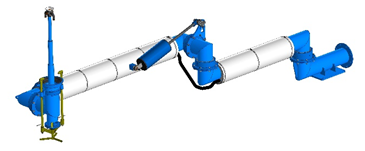

Devices for bottom discharge from USN type railway tanks

Devices of the USN type are designed for lower discharge of oil and oil products, as well as aggressive and non-aggressive liquids from railway tank cars. The devices are used in the oil, petrochemical and chemical industries.

Devices of the USN type are designed for lower discharge of oil and oil products, as well as aggressive and non-aggressive liquids from railway tank cars. The devices are used in the oil, petrochemical and chemical industries.

Devices of the USN type is a hinged pipeline that provides a closed system for draining the product from railway tanks.

Devices are manufactured with nominal bore diameters of 150, 175 and 200 mm, coverage area of 4 and 6 meters. It is possible to complete the devices with a hydromonitor, a steam jacket, an electric heating system, and various sensors.

The devices are equipped with a spring balancer with a protective cover, ensuring the safety of the operating personnel. Self-closing clamps securely fix the connecting head of the USN to the drain device of the railway tank, which reduces the time for preparatory work.

The tacks are controlled by one steering wheel, which greatly simplifies the process of attaching a railway tank to the drain device. The sealing of the connection head ensures a tight connection with the drain device of the tank during the draining process.

Devices for top loading into railway tanks of the UNZH type

UNZh type devices are designed for top loading of oil and oil products, as well as aggressive and non-aggressive liquids into railway tanks. The devices are used in the oil, petrochemical and chemical industries.

Devices are manufactured with nominal bore diameters of 150, 175 and 200 mm, coverage area of 4 and 6 meters. It is possible to complete the devices with a hydromonitor, a steam jacket, an electric heating system, and various sensors.

The devices are equipped with a spring balancer with a protective cover, ensuring the safety of the operating personnel. Self-closing clamps securely fix the connecting head of the USN to the drain device of the railway tank, which reduces the time for preparatory work.

The tacks are controlled by one steering wheel, which greatly simplifies the process of attaching a railway tank to the drain device. The sealing of the connection head ensures a tight connection with the drain device of the tank during the draining process.

Devices for top loading into railway tanks of the UNZH type

UNZh type devices are designed for top loading of oil and oil products, as well as aggressive and non-aggressive liquids into railway tanks. The devices are used in the oil, petrochemical and chemical industries.

Device type UNZH is a pivotally connected pipeline with a filling tip for dispensing the pumped product.

Are made in two design executions - the console and a strut. The riser version implies a loading device with its own support post and a foundation plate for fixing the proposed loading station to the foundation. The console version is used in cases of attaching the device to existing metal structures (trestle, mast, column). Based on the requirements for the UNZh installation, the supply of oil products can be both from above and from below. To balance the device can be used: a system of counterweights or a spring balancer.

The system of counterweights for balancing UZH allows you to effortlessly control the device. Setting up this system is simple in comparison with similar balancing devices.

The spring balancer for balancing the UNZH allows you to reduce the size of the loading device while maintaining reliable and easy control. The advanced swivel system makes it easy to obtain a filling device with left or right side execution, without any modifications.

Are made in two design executions - the console and a strut. The riser version implies a loading device with its own support post and a foundation plate for fixing the proposed loading station to the foundation. The console version is used in cases of attaching the device to existing metal structures (trestle, mast, column). Based on the requirements for the UNZh installation, the supply of oil products can be both from above and from below. To balance the device can be used: a system of counterweights or a spring balancer.

The system of counterweights for balancing UZH allows you to effortlessly control the device. Setting up this system is simple in comparison with similar balancing devices.

The spring balancer for balancing the UNZH allows you to reduce the size of the loading device while maintaining reliable and easy control. The advanced swivel system makes it easy to obtain a filling device with left or right side execution, without any modifications.

UNZh can be equipped with a filling tip for both open filling and sealed with a vapor removal sleeve. The tip for hermetic filling can be made at the request of the customer in the form of a cone or a cap, depending on the type of tanks being poured. The filling pipe can be solid or telescopic, which allows to reduce the size and facilitate the process of bringing the device into working position. The conditional diameter of the passage of the device is possible 100 and 80 mm.

Easy movement of devices without distortions is provided by three-row hinges. (two ball tracks and one roller, providing easy movement of the device without distortion throughout the entire service life, the roller track perceives significant lateral forces, which can significantly increase the life of the hinge before replacing it).

The design of the filling devices ensures the complete release of the filling pipe from the product and excludes the possibility of its spillage onto the tank at the end of the filling.

The design of the filling devices ensures the complete release of the filling pipe from the product and excludes the possibility of its spillage onto the tank at the end of the filling.

The devices have several levels of automation depending on the requirements put forward to the filling control method:

- Without control - the device does not have any shut-off or control valves;

- Manual termination - the device is completed with a butterfly valve directly on the loading device or shut-off valves installed in front of the device;

- Automatic loading stop - the device is equipped with a shut-off filling valve DKP-80/1, which works without the use of electricity;

- Control system based on a programmable logic controller and electrically controlled shut-off valves. Execution is possible with remote control of the filling (draining) process using the software of the operator's automated workstation;

- Commercial accounting of shipped products by volume and (or) weight.

- Without control - the device does not have any shut-off or control valves;

- Manual termination - the device is completed with a butterfly valve directly on the loading device or shut-off valves installed in front of the device;

- Automatic loading stop - the device is equipped with a shut-off filling valve DKP-80/1, which works without the use of electricity;

- Control system based on a programmable logic controller and electrically controlled shut-off valves. Execution is possible with remote control of the filling (draining) process using the software of the operator's automated workstation;

- Commercial accounting of shipped products by volume and (or) weight.

EQUIPMENT FOR RAILWAY TRANSPORT

EQUIPMENT FOR AUTOMOBILE TRANSPORT

Devices of the ASN type are designed for top loading and bottom loading/unloading of oil and oil products, as well as aggressive and non-aggressive liquids into road tanks. The devices are used in the oil, petrochemical and chemical industries.

Devices of the ASN type are easy to operate and are suitable for necks of any diameter, locking systems and lid opening angles. Are made in two design executions - the console and a strut.

The riser version implies a loading device with its own support post and a foundation plate for fixing the proposed loading station to the foundation.

The console version is used in cases of attaching the device to existing metal structures (trestle, mast, column). Based on installation requirements, the product inlet can be either from above or from below.

Devices of the ASN type are easy to operate and are suitable for necks of any diameter, locking systems and lid opening angles. Are made in two design executions - the console and a strut.

The riser version implies a loading device with its own support post and a foundation plate for fixing the proposed loading station to the foundation.

The console version is used in cases of attaching the device to existing metal structures (trestle, mast, column). Based on installation requirements, the product inlet can be either from above or from below.

To balance devices of the ASN type, the following can be used: a system of counterweights (weight) or a spring balancer (shock absorber). The system of counterweights for balancing the ASN allows you to effortlessly control the device. Setting up this system is simple in comparison with similar balancing devices.

The spring balancer for balancing the ASN allows you to reduce the size of the loading device while maintaining reliable and easy control and facilitate the process of bringing the device into working position.The devices are equipped with a locking mechanism in the working position; when performing operations, they exclude spontaneous movement of mechanisms.

The spring balancer for balancing the ASN allows you to reduce the size of the loading device while maintaining reliable and easy control and facilitate the process of bringing the device into working position.The devices are equipped with a locking mechanism in the working position; when performing operations, they exclude spontaneous movement of mechanisms.

The devices can be equipped with both a solid filling pipe and a telescopic one. The retractable telescopic tip provides the length necessary for safe contact with the bottom of any tanker or the distance from the end of the filling device to the lower generatrix of the tank did not exceed 200 mm. The tip is made of non-sparking material and its design prevents the product jet from falling and splashing at the beginning of the pouring operation.

Also in the set of devices it is possible to use a transitional cone, which takes into account the variety of diameters of the tanker necks. The safety of the product filling process is ensured by the sensor of the limit (emergency) filling level of the truck tank, which ensures that the working medium does not overflow over the edge of the tank neck.

Easy movement of devices without distortions is provided by three-row hinges. Two ball tracks and one roller, providing easy movement of devices without distortions during the entire service life, the roller track perceives significant lateral forces, which can significantly increase the life of the hinge before replacing it.

The design of the filling devices ensures the complete release of the filling pipe from the product and excludes the possibility of its spillage onto the tank at the end of the filling. The collection of drops and possible residues of oil products from the filling device, which is in the garage position, is carried out in a drip collector.

ASN-N type bottom loading/unloading devices are designed for sealed bottom loading/unloading of oil and oil products into road tanks. ASN-N is connected with API 1004, CamLock, KAMVALOK, PVA and other types to the valve of the tank truck, the steam outlet sleeve is connected to the vapor outlet valve. Bottom discharge/filling devices are completely hermetic, which eliminates the loss of product due to volatilization of the vapor-air mixture. They also allow filling simultaneously into several tank compartments, which significantly saves the downtime of the tank truck under loading.

ASN-N type bottom loading/unloading devices are designed for sealed bottom loading/unloading of oil and oil products into road tanks. ASN-N is connected with API 1004, CamLock, KAMVALOK, PVA and other types to the valve of the tank truck, the steam outlet sleeve is connected to the vapor outlet valve. Bottom discharge/filling devices are completely hermetic, which eliminates the loss of product due to volatilization of the vapor-air mixture. They also allow filling simultaneously into several tank compartments, which significantly saves the downtime of the tank truck under loading.

The devices have several levels of automation depending on the requirements put forward to the filling control method:

- Without control - the device does not have any shut-off or control valves.

- Manual termination - the device is completed with a butterfly valve directly on the loading device or shut-off valves installed in front of the device;

- Automatic loading stop - the device is equipped with a shut-off filling valve DKP-80/1, which works without the use of electricity;

- Control system based on a programmable logic controller and electrically controlled shut-off valves;

- Commercial accounting of shipped products by volume and (or) weight.

- Without control - the device does not have any shut-off or control valves.

- Manual termination - the device is completed with a butterfly valve directly on the loading device or shut-off valves installed in front of the device;

- Automatic loading stop - the device is equipped with a shut-off filling valve DKP-80/1, which works without the use of electricity;

- Control system based on a programmable logic controller and electrically controlled shut-off valves;

- Commercial accounting of shipped products by volume and (or) weight.

To get the consultation

EQUIPMENT FOR RAILWAY TRANSPORT

Devices for bottom discharge from USN type railway tanks

Devices of the USN type are designed for lower discharge of oil and oil products, as well as aggressive and non-aggressive liquids from railway tank cars. The devices are used in the oil, petrochemical and chemical industries.

Devices of the USN type is a hinged pipeline that provides a closed system for draining the product from railway tanks.

Devices of the USN type are designed for lower discharge of oil and oil products, as well as aggressive and non-aggressive liquids from railway tank cars. The devices are used in the oil, petrochemical and chemical industries.

Devices of the USN type is a hinged pipeline that provides a closed system for draining the product from railway tanks.

Devices are manufactured with nominal bore diameters of 150, 175 and 200 mm, coverage area of 4 and 6 meters. It is possible to complete the devices with a hydromonitor, a steam jacket, an electric heating system, and various sensors.

The devices are equipped with a spring balancer with a protective cover, ensuring the safety of the operating personnel. Self-closing clamps securely fix the connecting head of the USN to the drain device of the railway tank, which reduces the time for preparatory work.

The tacks are controlled by one steering wheel, which greatly simplifies the process of attaching a railway tank to the drain device. The sealing of the connection head ensures a tight connection with the drain device of the tank during the draining process.

Devices for top loading into railway tanks of the UNZH type

UNZh type devices are designed for top loading of oil and oil products, as well as aggressive and non-aggressive liquids into railway tanks. The devices are used in the oil, petrochemical and chemical industries.

The devices are equipped with a spring balancer with a protective cover, ensuring the safety of the operating personnel. Self-closing clamps securely fix the connecting head of the USN to the drain device of the railway tank, which reduces the time for preparatory work.

The tacks are controlled by one steering wheel, which greatly simplifies the process of attaching a railway tank to the drain device. The sealing of the connection head ensures a tight connection with the drain device of the tank during the draining process.

Devices for top loading into railway tanks of the UNZH type

UNZh type devices are designed for top loading of oil and oil products, as well as aggressive and non-aggressive liquids into railway tanks. The devices are used in the oil, petrochemical and chemical industries.

Device type UNZH is a pivotally connected pipeline with a filling tip for dispensing the pumped product.

Are made in two design executions - the console and a strut. The riser version implies a loading device with its own support post and a foundation plate for fixing the proposed loading station to the foundation. The console version is used in cases of attaching the device to existing metal structures (trestle, mast, column). Based on the requirements for the UNZh installation, the supply of oil products can be both from above and from below. To balance the device can be used: a system of counterweights or a spring balancer.

Are made in two design executions - the console and a strut. The riser version implies a loading device with its own support post and a foundation plate for fixing the proposed loading station to the foundation. The console version is used in cases of attaching the device to existing metal structures (trestle, mast, column). Based on the requirements for the UNZh installation, the supply of oil products can be both from above and from below. To balance the device can be used: a system of counterweights or a spring balancer.

The system of counterweights for balancing UZH allows you to effortlessly control the device. Setting up this system is simple in comparison with similar balancing devices.

The spring balancer for balancing the UNZH allows you to reduce the size of the loading device while maintaining reliable and easy control. The advanced swivel system makes it easy to obtain a filling device with left or right side execution, without any modifications.

The spring balancer for balancing the UNZH allows you to reduce the size of the loading device while maintaining reliable and easy control. The advanced swivel system makes it easy to obtain a filling device with left or right side execution, without any modifications.

UNZh can be equipped with a filling tip for both open filling and sealed with a vapor removal sleeve. The tip for hermetic filling can be made at the request of the customer in the form of a cone or a cap, depending on the type of tanks being poured. The filling pipe can be solid or telescopic, which allows to reduce the size and facilitate the process of bringing the device into working position. The conditional diameter of the passage of the device is possible 100 and 80 mm.

Easy movement of devices without distortions is provided by three-row hinges. (two ball tracks and one roller, providing easy movement of the device without distortion throughout the entire service life, the roller track perceives significant lateral forces, which can significantly increase the life of the hinge before replacing it)

The design of the filling devices ensures the complete release of the filling pipe from the product and excludes the possibility of its spillage onto the tank at the end of the filling.

The design of the filling devices ensures the complete release of the filling pipe from the product and excludes the possibility of its spillage onto the tank at the end of the filling.

- Automatic loading stop - the device is equipped with a shut-off filling valve DKP-80/1, which works without the use of electricity;

- Control system based on a programmable logic controller and electrically controlled shut-off valves. Execution is possible with remote control of the filling (draining) process using the software of the operator's automated workstation;

- Commercial accounting of shipped products by volume and (or) weight.

- Control system based on a programmable logic controller and electrically controlled shut-off valves. Execution is possible with remote control of the filling (draining) process using the software of the operator's automated workstation;

- Commercial accounting of shipped products by volume and (or) weight.

The devices have several levels of automation depending on the requirements put forward to the filling control method:

- Without control - the device does not have any shut-off or control valves;

- Manual termination - the device is completed with a butterfly valve directly on the loading device or shut-off valves installed in front of the device;

- Without control - the device does not have any shut-off or control valves;

- Manual termination - the device is completed with a butterfly valve directly on the loading device or shut-off valves installed in front of the device;

To get the consultation

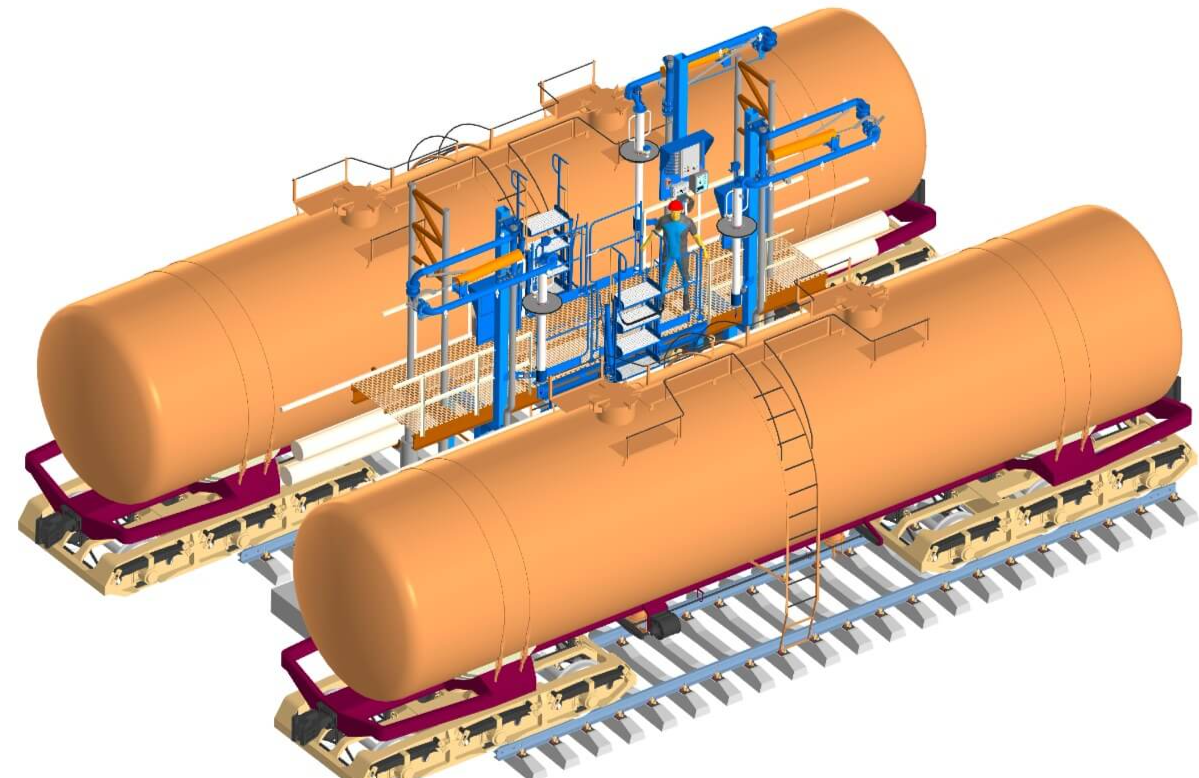

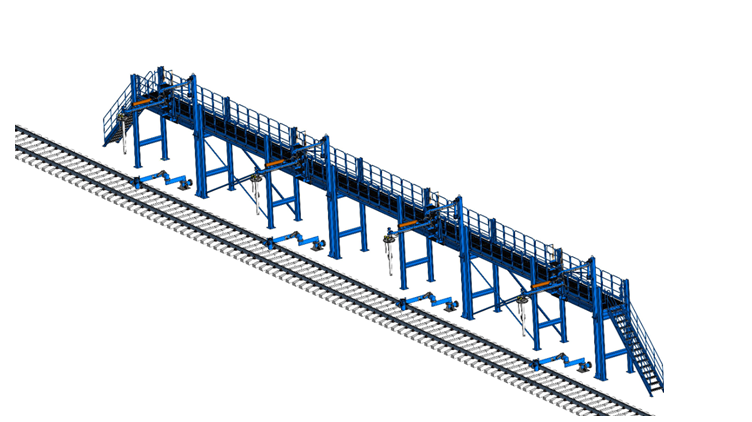

RAILWAY RACKS FOR DRAINING AND FILLING PRODUCTS

The railway overpass is designed for supply and collection of goods transported in railway tanks, loading and unloading of oil, oil products and other liquids, as well as providing the possibility of passing over the tracks when they are loaded.

The overpass provides simultaneous maintenance of several railway tanks (depending on the number of posts), fixation of the transitional bridge depending on its position in space, lifting of the bridge after the departure of the attendants, placement of equipment for loading and unloading oil products and other liquids. It can be equipped with a supply for connecting measuring complexes. The design of the rack allows you to increase and expand the number of loading posts, as well as to carry out phased installation and modernization of equipment.

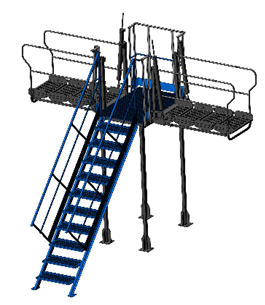

Service platforms for access to railway tanks of the POG type

The overpass provides simultaneous maintenance of several railway tanks (depending on the number of posts), fixation of the transitional bridge depending on its position in space, lifting of the bridge after the departure of the attendants, placement of equipment for loading and unloading oil products and other liquids. It can be equipped with a supply for connecting measuring complexes. The design of the rack allows you to increase and expand the number of loading posts, as well as to carry out phased installation and modernization of equipment.

Service platforms for access to railway tanks of the POG type

Service platforms are intended for access to truck tanks, when dispensing oil, oil products and other liquids, and for safe loading and unloading operations at oil product supply facilities. They can be part of other devices designed for top filling and draining or product accounting.

Transitional bridges MP

Transition bridges are designed to provide safe access to road and rail tank cars in order to perform loading and unloading operations, inspection, sampling, etc.

Transition bridges are designed to provide safe access to road and rail tank cars in order to perform loading and unloading operations, inspection, sampling, etc.

Service platforms are designed for access to railway tanks, when dispensing oil, oil products and other liquids, and for safe loading and unloading operations at oil product supply facilities. They can be part of other devices designed for top filling and draining or product accounting.

Service platforms for access to automobile tanks of the PO type

According to the principle of operation, the transition bridge is a structure consisting of a parallelogram mechanism with hinged steps, due to which the steps always remain in a horizontal position.

Two spring-type shock absorbers serve as a balancing mechanism for the transitional bridge.

Two spring-type shock absorbers serve as a balancing mechanism for the transitional bridge.

In the garage position on the flyover, the MP bridge handrails are in a vertical position and are held by a latch (garage position lock).

If it is necessary to maintain the tank along the entire length, the transitional bridge is equipped with a special mechanism (MTP longitudinal movement mechanism), which allows free movement along the entire overpass.

For safety during the operation of the bridge with MPP, guardrail posts or rotary guardrails are installed.

The intrinsic safety of the product is achieved through the use of intrinsically safe materials (copper, brass, polyamide) in friction pairs.

Bridges are made in intrinsically safe design, which allows them to be used in hazardous areas.

If it is necessary to maintain the tank along the entire length, the transitional bridge is equipped with a special mechanism (MTP longitudinal movement mechanism), which allows free movement along the entire overpass.

For safety during the operation of the bridge with MPP, guardrail posts or rotary guardrails are installed.

The intrinsic safety of the product is achieved through the use of intrinsically safe materials (copper, brass, polyamide) in friction pairs.

Bridges are made in intrinsically safe design, which allows them to be used in hazardous areas.

To get the consultation

Moscow, st. Skladochnaya, 1,

building 18, entrance 8, floor 3 office 318

+7 (495) 137-97-81

info@td-yugneftemash.ru

sale@td-yugneftemash.ru

info@td-yugneftemash.ru

sale@td-yugneftemash.ru

Moscow, st. Skladochnaya, 1,

building 18, entrance 8, floor 3 office 318

+7 (495) 137-97-81

info@td-yugneftemash.ru

sale@td-yugneftemash.ru

info@td-yugneftemash.ru

sale@td-yugneftemash.ru